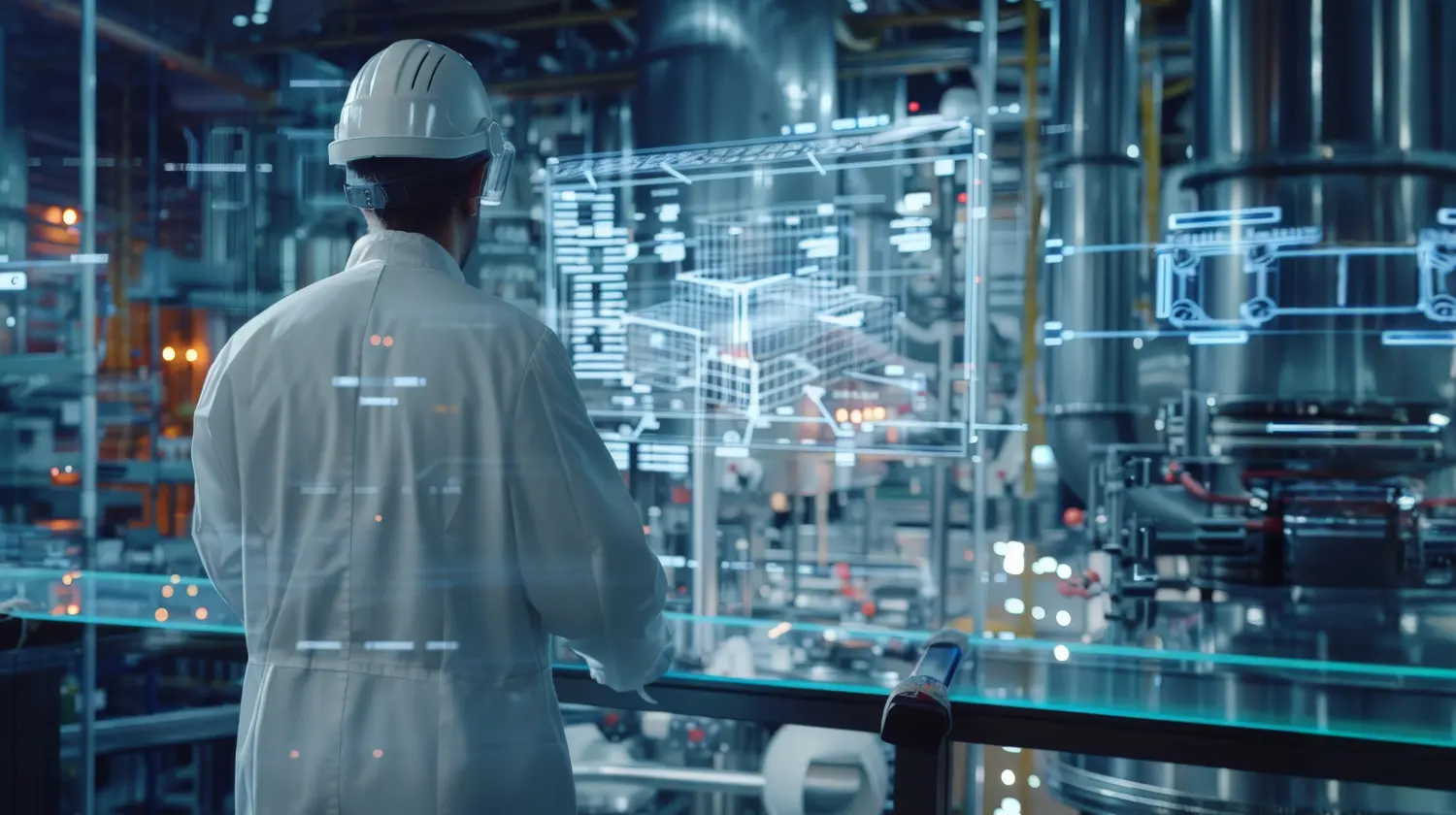

CMMS stands for Computerized Maintenance Management System. It is software that centralizes equipment information, optimizes maintenance processes, and improves asset utilization. It helps maintenance teams record all assets under their responsibility, schedule and track maintenance tasks, and maintain a history of the work they perform.

In detail, CMMS software optimizes the usage and availability of facility equipment by providing real-time equipment status information, helping managers make more informed decisions. By effectively utilizing data, enterprises can identify potential problems early, reduce equipment failure rates, and extend equipment service life.

Core Functions of CMMS

The core of modern enterprise management is improving efficiency, reducing costs, and controlling risks. As a vital component of modern equipment management systems, the core functions of a CMMS include: Asset Register, Work Order Management, Inventory Management, Preventive Maintenance, and Reporting & Analytics.

Asset Register

The Asset Register is the core module of CMMS software, primarily responsible for the detailed recording and storage of asset data within an enterprise or organization. It acts like an asset’s “household register,” meticulously documenting key information throughout the entire lifecycle of each asset—from acquisition and use to disposal—such as asset name, asset tag number, purchase date, purchase price, using department, etc.

Many maintenance teams must manage assets that are 10, 20, or even 30 years old. These machines have extensive repair histories. When a device failure occurs, it’s often useful to see how the same failure was resolved the last time. In a CMMS system, after a repair is completed, these failures are recorded in the asset’s history within the register and can be reviewed again by technicians.

Work Order Management

Work Order Management is a primary function of CMMS systems. Its core objective is to ensure every issue is handled promptly. It involves the systematic process of recording, assigning, tracking, and resolving user requests, internal tasks, or service problems. Each task or request generates a “work order,” which contains detailed information about the problem, its processing status, the responsible person, etc. Work order management plays a crucial role in internal operations and customer service, enhancing customer satisfaction and internal collaboration efficiency.

Work order management helps companies standardize task processing workflows through predefined workflow rules, ensuring each step is executed according to established standards. This not only improves work efficiency but also reduces the risk of human error. Simultaneously, it supports cross-departmental collaboration, ensuring complex problems can be resolved quickly.

Preventive Maintenance

Preventive Maintenance (PM) refers to performing scheduled maintenance activities to help prevent unexpected failures in the future. Simply put, it’s fixing things before they break. Large-scale equipment heavily relies on regular maintenance. Preventive maintenance extends the lifespan of equipment and facilities to maintain full production efficiency and avoid costly, time-consuming mechanical breakdowns.

For enterprises with large amounts of equipment, preventive maintenance schedules can be highly complex. To better manage equipment maintenance, improve maintenance efficiency, and reduce equipment failures, using a CMMS system for management becomes essential. This ensures facilities are adequately maintained while minimizing downtime and lowering production costs.

Inventory Management

Inventory management in enterprise operations is notoriously difficult due to its wide scope, high workload, and requirement for strong departmental coordination. A problem at any connection point can lead to insufficient inventory or overstocking.

Inventory management within a CMMS provides accurate inventory data through the counting, allocation, and retrieval of parts across storage areas, equipment maintenance, and materials. It helps enterprises better track spare parts inventory, avoiding downtime caused by missing critical components while also preventing budget pressure from over-purchasing. Additionally, it enables automatic replenishment by tracking inventory costs and managing suppliers, further improving enterprise management efficiency.

Reporting and Analytics

Generating various cross-category reports—such as asset availability, material usage, labor and material costs, and supplier evaluations—is a core strength of CMMS software. Analyzing this information provides insights into asset availability, performance trends, inventory optimization, and more, thereby supporting business decisions. It also collects and organizes information for audits.

Application Scenarios of CMMS in Different Fields

Before the advent of CMMS software, achieving centralized, dynamic visibility of data and automated equipment management was virtually impossible. Maintenance information was initially hidden in paper files and later scattered across multiple spreadsheets. Starting in the 1960s and continuing to the present, with continuous technological upgrades, CMMS software functionality has expanded to include mobile devices, field applications, and operational sites.

CMMS systems play a crucial role across various industries. These include manufacturing, oil and gas production, power generation, construction, transportation, and other sectors where physical infrastructure is critical.

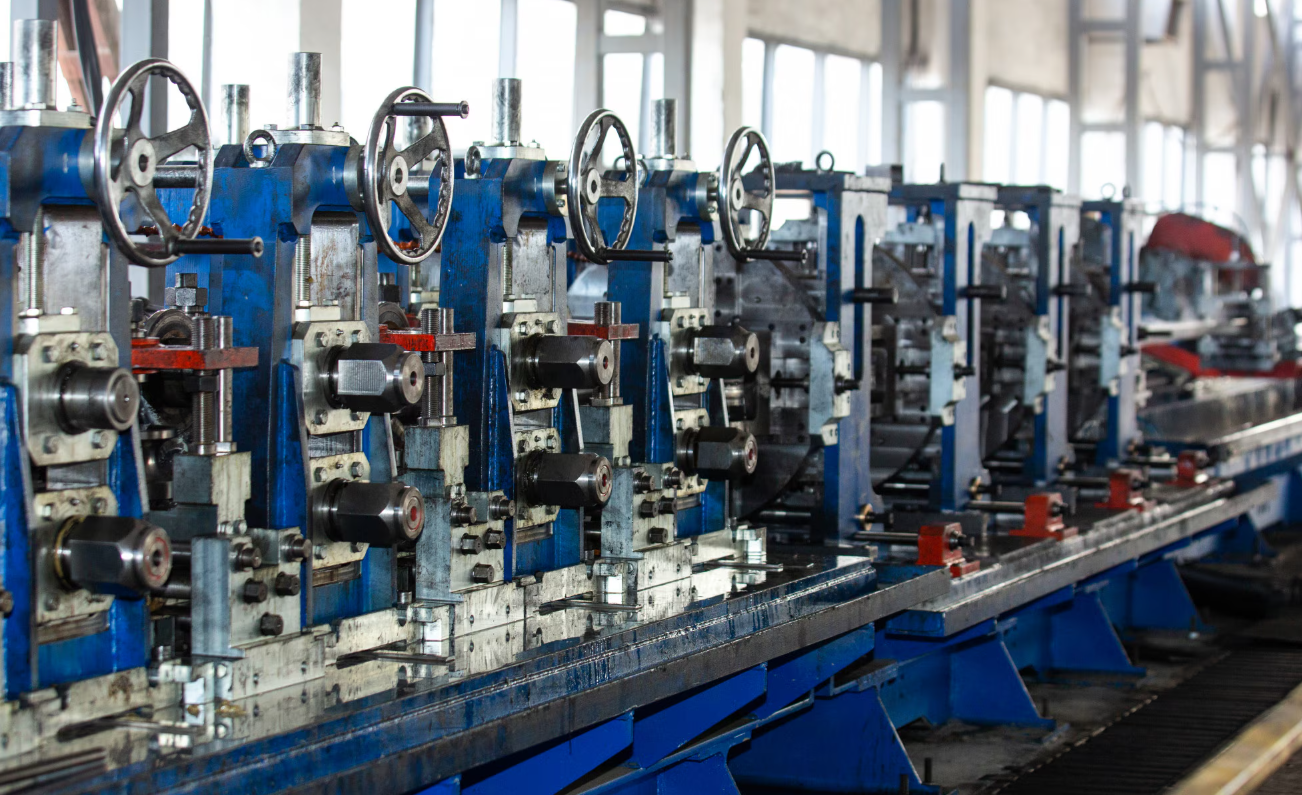

Manufacturing is one of the most widespread application areas for CMMS. Through CMMS systems, manufacturing enterprises can effectively manage the maintenance of production equipment, ensuring the efficient operation of production lines.

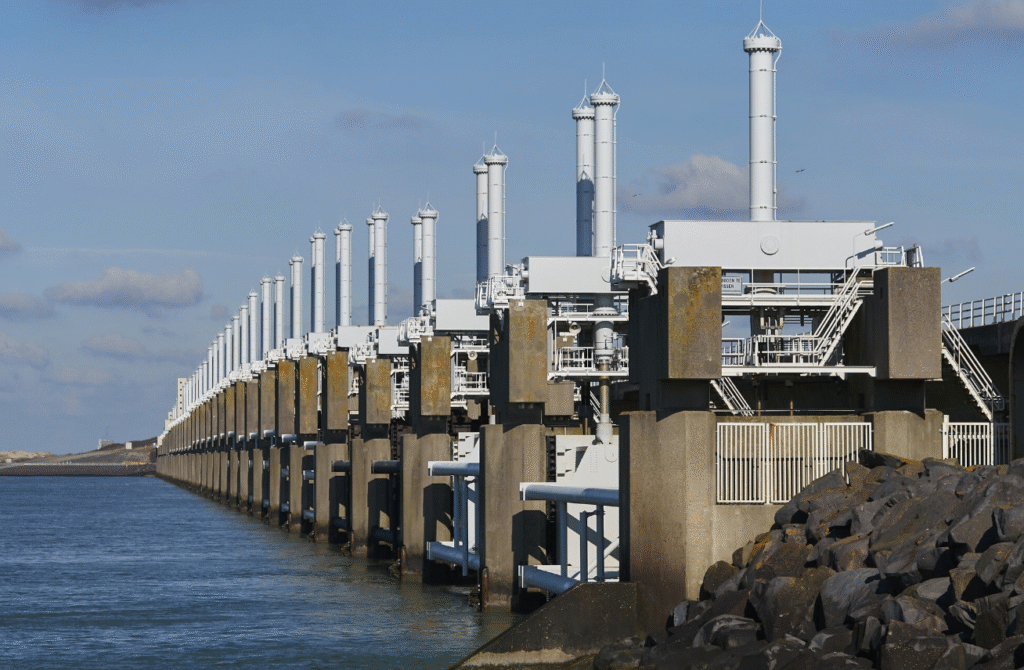

The energy industry is also a key application area for CMMS. Energy companies typically possess large amounts of complex equipment. CMMS helps these enterprises monitor equipment operating status in real-time, perform timely maintenance, and avoid costly shutdowns caused by equipment failures.

Equipment management in the healthcare industry is increasingly reliant on CMMS systems. Medical institutions like hospitals need to manage numerous medical devices. CMMS helps these organizations track device usage and maintenance status, ensuring equipment functions correctly, thereby guaranteeing the quality of healthcare services.

Furthermore, industries like transportation, utilities, and government agencies are gradually adopting CMMS systems to enhance the level and efficiency of their equipment management.

In today’s context of digital transformation, adopting management tools like CMMS has become a vital means for enterprises to improve operational efficiency. Choosing the right system and effectively utilizing its features will help enterprises remain competitive in the fierce market environment.