The Enterprise Asset Management (EAM) system is a core tool for modern enterprises to achieve refined operational management of physical assets. Its value focuses on two key management dimensions.

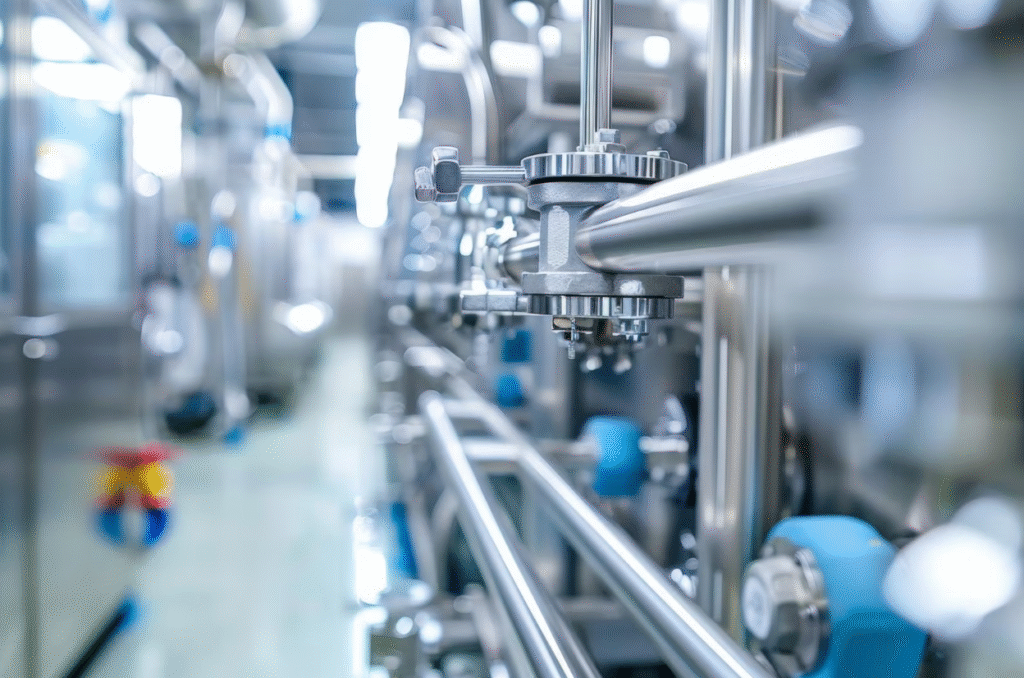

The first dimension is material storage and usage management, spanning the entire process from spare parts procurement and smart warehousing to precise issuance. This ensures traceability of critical materials and supply-demand balance, avoiding resource waste and production interruptions caused by inventory overstocking or shortages.

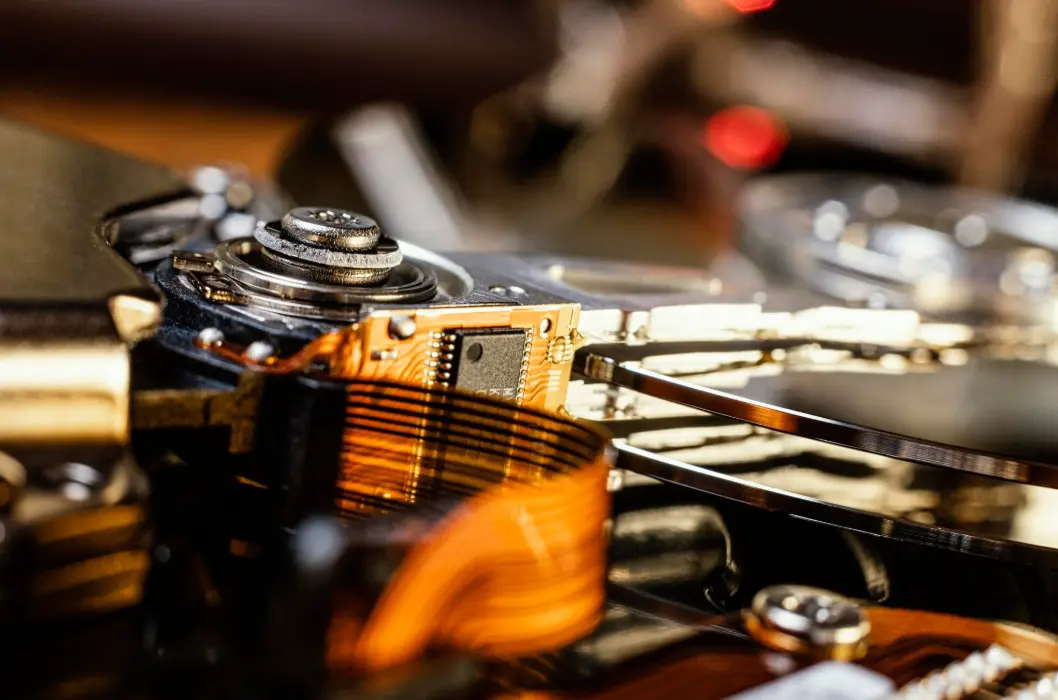

The second dimension is equipment maintenance and monitoring management, covering the establishment of equipment records, formulation of preventive maintenance plans, real-time status monitoring (especially via IoT technology), rapid fault response, and closed-loop processing of repair work orders. The aim is to maximize equipment availability and extend its lifecycle. These two core functions work synergistically to build a data-driven asset operation system, helping enterprises reduce maintenance costs, minimize unplanned downtime, and enhance overall operational efficiency.

I. Core Functional Requirements: The Three Pillars of a User-Friendly Enterprise Asset Management System

An excellent Enterprise Asset Management system acts as the intelligent hub for a company’s equipment assets. It integrates information flows and workflows across both domains in a structured, process-driven manner, breaking down information silos and efficiency bottlenecks inherent in traditional management. Ultimately, it achieves the core objectives of extending asset lifespan, maximizing asset availability, reducing total maintenance costs (including repair costs, spare parts inventory costs, and downtime losses), and ensuring production safety and continuity.

When evaluating an Enterprise Asset Management solution, functionality is the bedrock of success.The three pillars below define what truly user-friendly Enterprise Asset Management delivers:

1.Full Lifecycle Management in Enterprise Asset Management

An effective Enterprise Asset Management platform must establish a complete management chain that spans the asset’s journey from procurement and capitalization to decommissioning and disposal.

This means the system must initially create a digital asset register containing technical specifications, location coordinates, and supplier information, forming the core data foundation. During the operational maintenance phase, it must deeply integrate preventive maintenance scheduling, real-time condition-based predictive maintenance triggering mechanisms, and efficient work order response processes, while ensuring real-time linkage between maintenance actions and spare parts inventory dynamics.

Mobile inspection capabilities must allow frontline personnel to record equipment status (supporting photos, sensor readings, etc.) via handheld devices on custom routes, with the system automatically converting anomalies into pending work orders. In the asset decommissioning phase, standardized disposal approval and residual value assessment processes are required, while complete historical maintenance data is preserved to provide decision-making basis for next-generation asset selection. This comprehensively resolves information fragmentation issues, enabling full-cycle traceability of asset status and precise quantification of maintenance costs.

2.Usability and Real-Time Capability : Key Drivers of Field Efficiency

For Enterprise Asset Management systems, field execution effectiveness highly depends on user experience and data flow efficiency.

Role-based dashboards and minimalist interface design are fundamental requirements. For example, a technician should be able to report a fault by scanning a QR code with a mobile phone within 3 seconds, significantly reducing training costs. The mobile application must support offline operation, real-time work order push notifications, and spare parts consumption via scanning, ensuring work continuity in unstable network environments.

Deeper value lies in real-time linkage capabilities – by integrating IoT device sensors, the system can continuously monitor parameters like vibration and temperature, issuing early warnings for potential failures. Events such as inventory threshold alerts, overdue work orders, or abnormal equipment shutdowns should automatically trigger multi-channel notifications, compressing traditional response delays. Repair data entered in the field must be transmitted back to the central database in real-time, ensuring management decisions are based on a zero-latency operational overview. This “user-friendly interface + zero data delay” characteristic can significantly reduce unplanned downtime by over 30%.

3.Data Analysis and Reporting Capabilities: The Engine for Insight and Decision-Making

The ability to extract management insights from operational data is the decision engine of an Enterprise Asset Management system.

Visual dashboards need to dynamically aggregate key performance indicators (KPIs) like MTTR (Mean Time to Repair) and MTBF (Mean Time Between Failures), helping managers quickly identify bottlenecks. AI prediction models trained on historical data and real-time operational information should output equipment remaining useful life assessments and fault probability heatmaps, driving maintenance strategies from reactive fixes towards proactive intervention.

For highly regulated industries like energy or healthcare, one-click generation of compliance reports adhering to standards such as ISO 55000 can drastically reduce audit costs. The deeper value lies in cost insights – the system must break down data barriers between spare parts procurement, warehousing, labor, and production losses, building multi-dimensional cost allocation models. This enables precise quantification of the impact of downtime on revenue, providing irrefutable data evidence for optimizing annual maintenance budgets, ultimately transforming equipment data into a strategic asset for continuous improvement.

II. How to Choose : Key Decision Dimensions

After defining the core functional requirements, selecting from numerous vendors requires careful evaluation of the following key dimensions:

1.Deployment Method: Cloud (SaaS) vs. On-Premise

When implementing Enterprise Asset Management, deployment strategy must align with the company’s size and security needs.

Cloud deployment (SaaS), with its advantages of rapid implementation, low initial investment, and automatic upgrades, is the preferred choice for resource-constrained small and medium-sized enterprises (SMEs). It is particularly suitable for SMEs with limited budgets, weak IT resources, or scenarios requiring quick pilots. However, its data security heavily relies on the vendor’s commitments and platform capabilities, customization depth may be limited, and strict evaluation of the provider’s data encryption certifications and regional compliance (e.g., GDPR) is essential.

On-premise deployment installs the system on the company’s own servers, providing complete data control and meeting the highest security and compliance requirements, offering maximum customization flexibility. However, it entails high upfront hardware and software licensing costs, long implementation cycles, and requires significant in-house IT operational capabilities for ongoing maintenance and upgrades. It is typically better suited for large corporations or highly sensitive industries with stringent data security requirements. The choice requires balancing the company’s expectations regarding data sovereignty, security level, budget, IT capabilities, and future scalability. Hybrid models exist but are relatively complex.

2.Ensuring Enterprise Asset Management Adapts to Your Business Evolution

Few companies have identical business processes, so Enterprise Asset Management system’s adaptability directly determines its long-term value.

The system should possess sufficient flexibility to accommodate unique business rules, approval workflows, data fields, and report formats. Prioritize platforms supporting low-code configuration (e.g., drag-and-drop form builders, visual process designers) to avoid project cost overruns from custom development exceeding 30% of the total.

Scalability refers to the system’s ability to smoothly expand capacity and enhance functionality as the business grows (e.g., adding equipment, users, new plants, new business modules). An open API architecture is crucial for scalability, ensuring seamless future integration with ERP, MES, and IoT platforms. Modularly designed systems typically offer better scalability, allowing new modules to be purchased and activated as needed, providing flexibility for technological evolution.

3.Implementation Team Expertise: The Guardian of Project Success

The vendor’s implementation capability is often more critical than the software features alone. Focus on evaluating whether the vendor has successful case studies within your industry and possesses a mature, transparent project implementation methodology, including clear phase definitions, deliverables, and risk management. For multinational vendors, the technical response speed of the local support team should also be assessed.

4.Maintenance Services and Ongoing Support: Guarantee of Long-Term Value

An Enterprise Asset Management system is a production system used long-term; going live is just the starting point. Clearly define within the Service Level Agreement (SLA) the fault response escalation mechanism, including response times (e.g., 2/4/8 hours), problem resolution timeframes, and system uptime commitments (e.g., 99.9%). Clarify if the first year of maintenance is free, the subsequent annual maintenance fee percentage (typically 20%-25% of the software license fee), whether fees include patch updates and online support, and if major version upgrades incur extra charges. Clear maintenance terms are key to mitigating future risks and ensuring sustained value.

III. Towards the Future of Intelligent Asset Management

In the wave of digital transformation, choosing a user-friendly Enterprise Asset Management system is far more than a simple software purchase; it is a strategic investment impacting operational efficiency, cost control, and core competitiveness. A system combining deep functionality with an agile user experience has become essential for enterprises seeking cost reduction and efficiency gains.

Among the many solutions dedicated to helping businesses unlock asset potential, SAMEX Enterprise Asset Management deserves your close attention. By seamlessly integrating mobile and IoT capabilities, it empowers field personnel with an exceptionally user-friendly operational experience.

Its built-in AI-driven analytics engine further transforms equipment data into actionable optimization strategies. Whether seeking rapid cloud deployment or deep on-premise control, SAMEX offers flexible choices. Its unique low-code platform significantly reduces customization costs, ensuring the system precisely matches business scenarios. Backed by an implementation team with over 10 years of industry experience and 7×24 SLA support, SAMEX guarantees a smooth journey from deployment to ongoing operation. Choosing SAMEX is not just selecting a tool; it’s choosing a long-term partner committed to maximizing asset value through data.

A wise Enterprise Asset Management choice is the crucial first step towards opening a new chapter of lean, intelligent, and sustainable asset management.