In the era of industrial digital transformation, Enterprise Asset Management (EAM) has evolved from a traditional maintenance tool to a core driver of operational efficiency. However, traditional EAM systems face inherent limitations such as manual data silos, reactive maintenance, and inefficient decision-making. Today, AI in EAM is no longer a futuristic concept but a practical solution that is reshaping asset management landscapes across industries.

By integrating advanced algorithms, machine learning, and predictive analytics, AI-powered EAM systems are enabling businesses to shift from “firefighting” maintenance to proactive operations. The global EAM market is experiencing rapid growth driven by this integration, with authoritative industry research highlighting significant gains for early adopters:

- Increased Asset Uptime: According to Deloitte, predictive maintenance strategies can drive a 20% increase in asset availability.

- Reduced Unplanned Downtime: Top-tier analysis by McKinsey indicates that AI-driven maintenance can reduce machine downtime by up to 50%.

- Rapid Market Growth: The adoption of intelligent EAM solutions is projected to grow significantly, with market reports forecasting a CAGR of over 25% for the predictive maintenance sector in the coming years.

For asset-intensive industries such as manufacturing, energy, and transportation, these improvements translate to millions in annual cost savings and a critical competitive advantage.

The Limitations of Traditional EAM: Why AI Integration Is Imperative

Traditional EAM systems rely heavily on manual data entry and static maintenance schedules, which are increasingly unable to meet the demands of modern intelligent operations. These legacy systems typically struggle with three core challenges:

- Data Inaccuracy and Latency: Maintenance technicians often delay or omit updating work orders, resulting in incomplete asset histories. This lack of real-time data creates “blind spots” that hinder effective decision-making.

- Reactive Maintenance Models: Without predictive insights, businesses can only address equipment failures after they occur. This reactive approach leads to costly production disruptions and emergency repair expenses.

- Inefficient Resource Allocation: Manual scheduling often results in either over-maintenance (wasting time and resources) or under-maintenance (increasing failure risks), failing to optimize the workforce effectively.

Key Application Scenarios of AI in EAM: From Prediction to Autonomy

1. AI-Powered Predictive Maintenance: Minimizing Unplanned Downtime

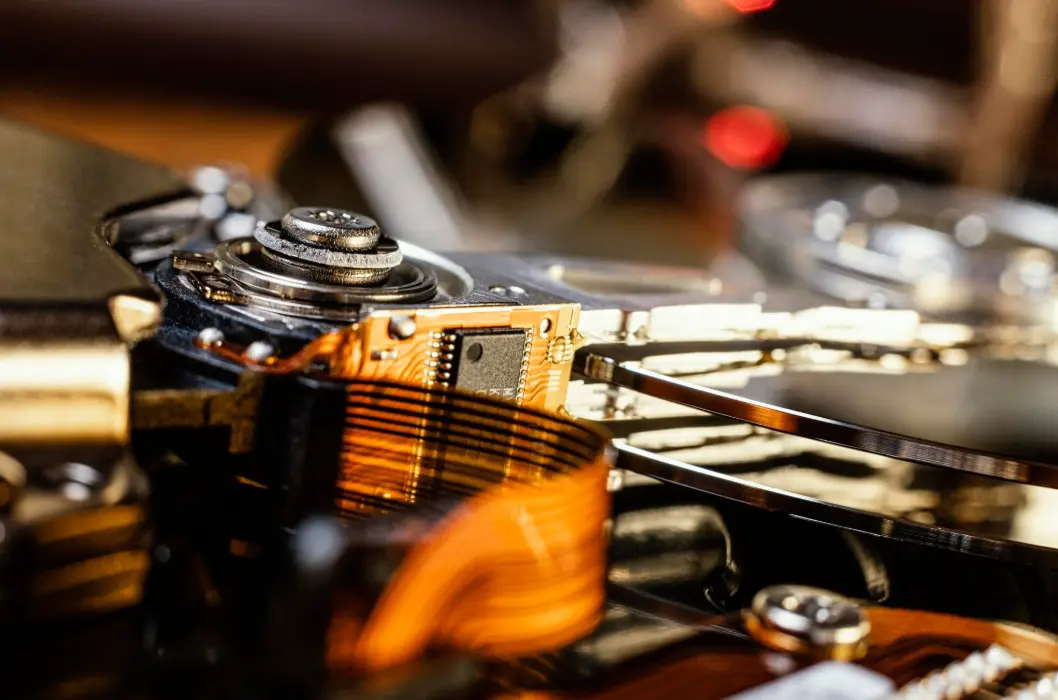

Predictive maintenance is the most mature and impactful application of AI in EAM. By analyzing real-time data from IoT sensors, equipment logs, and historical maintenance records, AI algorithms can identify subtle patterns and anomalies that indicate potential failures. For example, vibration analysis and temperature monitoring powered by machine learning can predict pump failures days or even weeks in advance. This allows maintenance teams to schedule repairs during non-peak hours. Research shows that this proactive approach can reduce overall maintenance costs by up to 40%. Leading intelligent EAM platforms have embedded industrial AI into their solutions, enabling reliability engineers to conduct FMECA analysis and optimize maintenance strategies with data-driven precision.

2. Agentic AI for Autonomous Safety and Compliance

An emerging trend in AI in EAM is the adoption of agentic AI – autonomous systems that proactively identify and address issues without constant human prompts. A notable use case is autonomous Environment, Health and Safety (EHS) incident reporting. Traditional safety reporting relies on manual documentation, leading to underreporting of near-misses and unsafe conditions. Agentic AI embedded in EAM workflows continuously scans work requests, automatically identifies safety-related content, and generates comprehensive incident reports with minimal human intervention. This ensures full visibility into workplace safety risks, enabling proactive risk mitigation and regulatory compliance.

3. AI-Driven Full Lifecycle Asset Management

AI in EAM extends beyond maintenance to optimize the entire asset lifecycle – from procurement to decommissioning. Natural Language Processing (NLP) technology parses equipment manuals and maintenance documents to automatically populate accurate asset ledgers, significantly reducing manual data entry errors. Machine learning algorithms also evaluate asset performance data to predict residual value, helping businesses make informed decisions on repair, replacement, or refurbishment. Additionally, AI integrates EAM data with ERP and MES systems, creating a unified data ecosystem that supports end-to-end asset lifecycle management and intelligent resource allocation.

4. AI-Powered Decision Support for Managers

For executives and operations managers, AI in EAM transforms raw data into actionable insights. Interactive dashboards powered by AI provide real-time visibility into asset health, maintenance costs, and resource utilization. Predictive analytics models forecast future maintenance budgets and resource needs, enabling data-driven strategic planning. A global food manufacturer, for instance, has leveraged AI in EAM to optimize asset throughput and utilization, driving better investment decisions across its fleet of production equipment. This shift from “data recording” to “decision enabling” is a key value driver of intelligent EAM systems.

Critical Considerations for Successful AI in EAM Implementation

While the benefits of AI in EAM are significant, successful implementation requires careful planning. First, data quality is foundational: AI algorithms rely on accurate, comprehensive data from sensors, work orders, and equipment histories. Businesses should invest in IoT integration and data cleansing processes to ensure reliable input. Second, solution selection must align with business needs: small to medium enterprises may benefit from lightweight, cloud-based AI modules, while large enterprises may require custom agentic AI frameworks. Third, change management and training are essential: maintenance teams need to adapt to new workflows, and upskilling programs ensure effective utilization of AI-powered tools. Finally, compliance with data security regulations is non-negotiable, especially for cross-border operations handling sensitive asset data.

The Future of AI in EAM: Toward Fully Autonomous Asset Management

The journey of AI in EAM is just beginning. Future advancements will see deeper integration with digital twins, enabling virtual simulation of asset performance and maintenance scenarios. Agentic AI will evolve to handle more complex tasks, from autonomous maintenance scheduling to real-time resource reallocation during operational disruptions. Additionally, the convergence of AI, IoT, and cloud computing will make intelligent EAM accessible to small and medium enterprises, democratizing access to advanced asset management capabilities. As PwC insights suggest, while full maturity is still evolving, the majority of industrial leaders are now prioritizing AI deployments to secure their future competitiveness.

In conclusion, AI in EAM is not just a technological upgrade but a strategic transformation that redefines how businesses manage their most valuable physical assets. By addressing traditional EAM limitations through predictive maintenance, autonomous safety management, and intelligent decision support, AI-powered systems drive tangible improvements in cost, efficiency, and risk management. As the future of asset management unfolds, businesses that embrace intelligent asset strategies will gain a decisive competitive edge in the digital economy. Whether you’re a manufacturing plant seeking to reduce downtime or an energy company optimizing infrastructure maintenance, the time to leverage this transformative technology is now.

Ready to transform your operations with SAMEX? Contact us today to schedule a personalized demo of our AI-driven EAM solution and discover how much you can save.