In today’s fiercely competitive manufacturing landscape, the drive to improve factory operational efficiency has become a core mandate for enterprises seeking to reduce costs and enhance core competitiveness. Traditional factories often rely on manual experience to manage equipment, facilities, and resources. This mode frequently leads to information lag, reactive maintenance, and hidden resource waste. According to a report cited by Forbes, unplanned downtime costs industrial manufacturers an estimated $50 billion annually, a staggering figure that severely constrains further development.

However, the synergistic application of Enterprise Asset Management (EAM) and Facility Management (FM) systems is breaking these bottlenecks. Through digital and intelligent means, these systems close the management loop, optimizing asset control, maintenance strategies, and resource scheduling. This article breaks down practical scenarios to demonstrate how EAM/FM systems can help manufacturers improve factory operational efficiency through precise optimization.

1. Digitalizing the Asset Lifecycle to Improve Factory Operational Efficiency

Factory assets are the core carriers of production operations. The quality of management for equipment, plants, and utilities directly dictates an enterprise’s output capability. Under traditional models, manual ledgers often face challenges such as scattered information, inefficient retrieval, and data distortion. This not only leads to asset idleness but also risks unexpected failures due to unclear equipment status. Therefore, the first step to improve factory operational efficiency is to build a unified digital management platform for refined control over the entire asset lifecycle.

Centralized Data Management and Retrieval

At the asset ledger level, the EAM system establishes a standardized database covering full-dimensional information such as equipment models, installation locations, maintenance history, spare parts associations, and energy consumption data. Imagine when a piece of equipment malfunctions; maintenance personnel no longer need to flip through thick logbooks. Instead, they can quickly retrieve past failure data through the system. This digital workflow can shorten troubleshooting time by over 30%, effectively avoiding prolonged downtime caused by information lag. Meanwhile, the FM system manages infrastructure such as plant buildings and utility networks, ensuring the perfect adaptation of the production site to the equipment. This holistic approach is essential to improve factory operational efficiency by minimizing production interruptions caused by facility issues.

Cost Control via Life Cycle Cost (LCC) Analysis

Furthermore, Life Cycle Cost (LCC) accounting provides key data support for asset optimization. The system tracks costs in real-time—from procurement and operation to disposal—while quantifying hidden costs like downtime losses. By comparing the cost-performance ratio of different assets, enterprises can phase out high-consumption equipment. For example, a manufacturing plant used the system to calculate LCC and discovered that the costs of an old air compressor were excessive. They immediately initiated an energy-saving retrofit. This move not only reduced long-term operating costs but also enhanced equipment stability, laying a solid foundation to improve factory operational efficiency.

2. Upgrading Maintenance Strategies: From Reactive Repair to Active Control

Equipment failure is one of the core pain points affecting factory capacity. The traditional “run-to-failure” mode not only incurs high repair costs but also causes uncontrollable downtime losses. The core value of EAM/FM systems lies in driving a shift in maintenance strategy from passive response to Preventive and Predictive Maintenance. This strategic shift is critical for any plant manager aiming to improve factory operational efficiency.

Precision through Preventive Maintenance (PM)

The precise implementation of Preventive Maintenance (PM) relies on the system’s automated scheduling capabilities. Based on factors such as equipment runtime and process parameters, the EAM system can preset personalized maintenance plans. Once conditions are met, the system automatically generates work orders. Compared to the extensive “periodic overhaul” mode, this precise maintenance avoids resource waste caused by over-maintenance. Taking a core device on a stamping line as an example, the system sets a rule to “change lubricating oil every 500 operating hours.” This reduces equipment downtime and lowers maintenance costs, directly driving the initiative to improve factory operational efficiency.

Reducing Downtime with Predictive Maintenance (PdM)

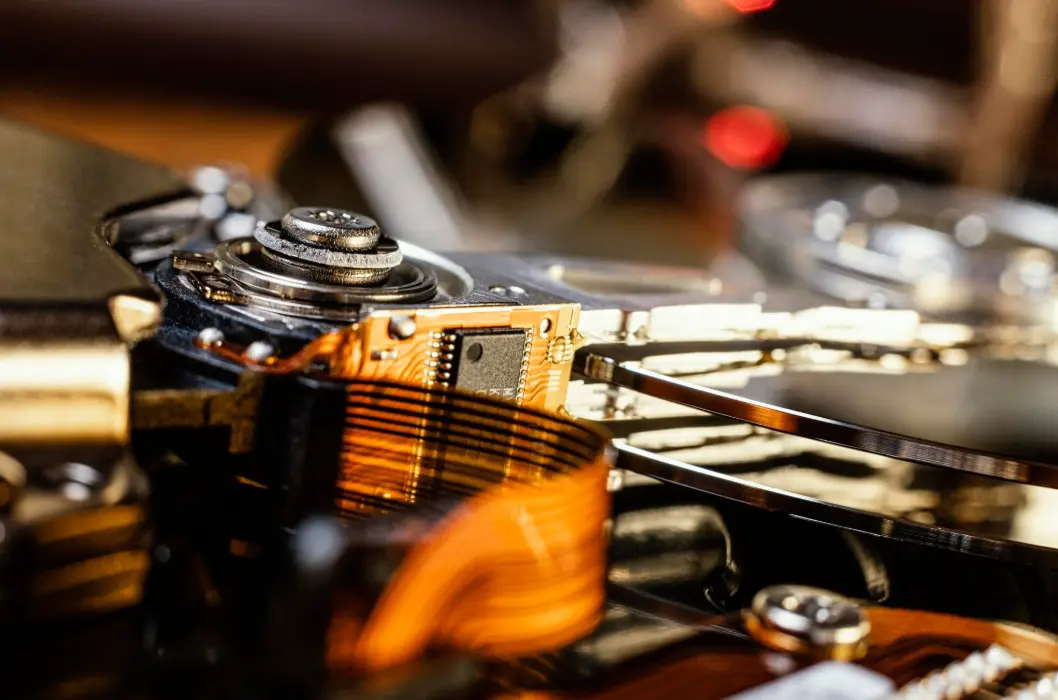

The intelligent application of Predictive Maintenance (PdM) further breaks through maintenance bottlenecks. By installing sensors for vibration and temperature and integrating real-time data into the EAM system, enterprises can use AI algorithms to anticipate potential risks. When data indicators exceed thresholds, the system automatically triggers alerts. According to the U.S. Department of Energy (FEMP), a functional predictive maintenance program can eliminate breakdowns by 70% to 75% and reduce maintenance costs by 25% to 30%. Additionally, the system supports closed-loop work order management, avoiding unclear responsibilities and optimizing personnel allocation. These measures significantly reduce the friction in maintenance workflows, helping to improve factory operational efficiency.

3. Collaborative Resource Scheduling: Lean Control to Minimize Waste

Efficient factory operations depend not only on stable equipment but also on the optimal configuration of manpower, spare parts, tools, and space. In traditional management, issues such as spare parts backlogs and idle personnel are common, causing significant resource waste. EAM/FM systems achieve lean resource management through global coordination, which is a vital component in the effort to improve factory operational efficiency.

Balancing Inventory with Lean Principles

Lean control of spare parts inventory is a core link in resource optimization. The system automatically calculates safety stock thresholds based on maintenance plans and failure frequencies, effectively balancing “backlog” against “stockout risks.” For high-value parts like inverters, a “Zero Inventory + JIT Delivery” mode can be adopted to reduce capital occupation. An auto parts factory optimized its inventory through this system, reducing backlog capital by 40% and dropping maintenance delays caused by stockouts. This reduction in waste is critical for any strategy designed to improve factory operational efficiency.

Smart Scheduling of Personnel and Tools

The collaborative scheduling of manpower and facilities further excavates operational potential. The EAM system displays the skill qualifications of maintenance personnel in real-time, enabling optimal dispatching—assigning high-precision tasks to qualified technicians. Simultaneously, the FM system manages facility resources such as workstations and transport tools. Production departments can book these resources in advance to avoid conflicts. This collaborative optimization allows factories to maximize overall output without increasing resource input, thereby serving to improve factory operational efficiency.

4. Data-Driven Decision Making: Continuous Iteration of Management Processes

In the digital age, data is the core engine driving change. The massive amount of data on equipment operation, maintenance, and costs accumulated by EAM/FM systems can be mined to become key decision-making evidence. Utilizing this data is arguably the most powerful way to improve factory operational efficiency in the long run.

Visualizing Key Performance Indicators (OEE & MTTR)

Visualization of operational metrics is the first step in data-driven decision-making. By building a management cockpit that displays core indicators such as OEE (Overall Equipment Effectiveness) and MTTR (Mean Time To Repair) in real-time, management can quickly pinpoint efficiency shortfalls. For instance, when the OEE of a production line remains low, data tracing can determine the root cause. An electronic component factory used this metric visualization to identify and resolve excessive MTTR issues, ultimately boosting that production line’s OEE by 12%. This proves that data visibility is key to improve factory operational efficiency.

Ensuring Compliance and Process Agility

Moreover, process optimization and compliance management also rely on data. By analyzing historical data, enterprises can continuously refine maintenance plans and inventory strategies, forming a closed loop of optimization. At the same time, the system automatically tracks compliance requirements such as annual equipment inspections, triggering expiration alerts. Compliance and a stable production order are important guarantees for the long-term goal to improve factory operational efficiency.

5. Breaking Information Silos: Cross-Departmental Collaboration

In traditional factories, departments such as production, maintenance, procurement, and finance often operate in silos. Information transmission relies on manual communication, leading to severe lags. As a unified digital platform, the EAM/FM system breaks down departmental barriers. Eliminating these silos is a prerequisite if an organization truly wants to improve factory operational efficiency.

Streamlining Workflows Across Departments

In daily operations, when the production department reports a fault, the maintenance department responds in real-time; the procurement department simultaneously views inventory status; the finance department tracks costs. This full-process collaboration avoids delays caused by lagging information. For example, a chemical plant shortened the average time from fault reporting to repair by 25%. The strengthening of cross-departmental collaboration transforms factory operations into an organic whole, effectively driving the organization to improve factory operational efficiency.

Conclusion

Using EAM/FM systems to improve factory operational efficiency is not merely an application of tools, but a reconstruction of management processes involving asset control, maintenance strategies, and resource scheduling. From passively responding to faults to actively predicting risks, and from experience-based decisions to data-driven insights, this system provides comprehensive digital support. For manufacturing enterprises, the key lies in combining their own production characteristics with the system’s functional advantages. In the future, the integration of EAM/FM systems with AI and IoT will become even tighter, opening up more possibilities to improve factory operational efficiency sustainably.