In a manufacturing workshop, a five-year-old injection molding machine suddenly stops working, and upon inspection, its core components are found to have worn out beyond safety thresholds due to prolonged use. Similarly, the central air conditioning system in an office building frequently breaks down every summer, leaving maintenance personnel scrambling between floors without identifying the root cause. These are common challenges faced by countless enterprises struggling with asset aging. As assets age, equipment failure rates increase by 15%-20% annually, not only driving up maintenance costs but also potentially causing production interruptions and service delays, which directly impact company revenue.

In reality, asset aging is not an unsolvable problem. Extending asset lifespan is the key to overcoming this challenge. By employing scientific management strategies, companies can extend the average lifespan of their assets by 20%-30%, reducing operational costs by 10%-15% annually. For companies pursuing refined management, extending asset lifespan is no longer an “optional action” but a “must-answer question” to achieve cost reduction and efficiency improvement.【Learn more data insights】

I. Scientific Strategies: Four Approaches to Extending Asset Lifespan

The root cause of asset aging is often not “long usage time” but rather “poor management.” Reactive maintenance, unbalanced upkeep, and improper spare part usage can all accelerate asset deterioration. To effectively extend asset lifespan, companies need to develop systematic solutions from four dimensions: maintenance, technology, spare parts, and data.

1. Establishing a Preventive Maintenance System: From “Reactive Repairs” to “Proactive Prevention”

The primary cause of premature asset aging is the “lag” in maintenance—many companies only repair equipment after it breaks down, at which point the wear and tear on components is often irreversible. The first step in extending asset lifespan is to establish a preventive maintenance system that ensures maintenance is performed before failures occur.

Dynamic Maintenance Planning: Develop multi-dimensional trigger conditions based on asset types. For instance, production equipment can be maintained based on “operating hours” (e.g., inspections every 500 hours), vehicles by “mileage” (e.g., oil changes every 10,000 kilometers), and elevators by “usage frequency” (e.g., safety device calibration every month). In the chemical industry, reaction vessels in contact with corrosive materials require maintenance cycles shortened by 30%, whereas lighting systems in office buildings can be checked quarterly to avoid “one-size-fits-all” maintenance that leads to either insufficient or excessive upkeep.

Standardized Maintenance Procedures: Create a “Standard Operating Procedure” (SOP) for each asset, detailing steps, tools, spare part specifications, and critical control points (e.g., bearing clearance must be controlled between 0.02-0.05mm). Use mobile devices to record maintenance processes, including photos and data entry, ensuring every maintenance task is “traceable and verifiable” to avoid incomplete work due to operator variability.

2. Applying Predictive Maintenance Technology: Detecting “Aging Signals” in Advance

If preventive maintenance is akin to “scheduled check-ups,” predictive maintenance is like “real-time monitoring.” By capturing abnormal signals during asset operation, potential failures can be identified early, further extending asset lifespan.

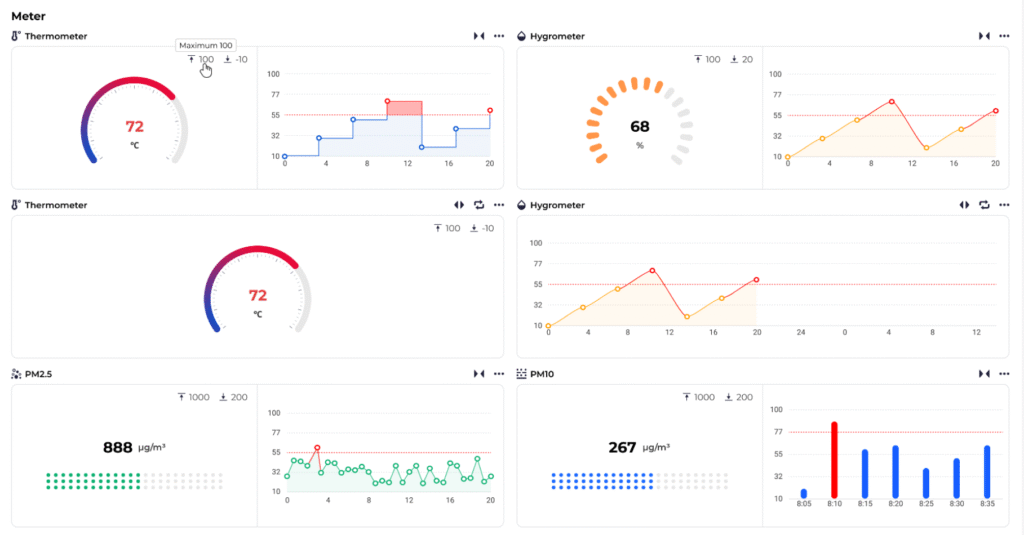

IoT Data Collection: Install sensors on critical assets to monitor parameters such as temperature, vibration, and pressure in real time. For example, when motor bearings wear out, vibration frequency may increase from 50Hz to over 80Hz; when transformer insulation ages, oil temperature may rise by 10-15°C. These data points provide a clear indication of an asset’s “health status.” A steel mill that installed vibration sensors on its blast furnace fans detected bearing abnormalities three days in advance, preventing shaft breakage and extending the fan’s lifespan by two years.

Remaining Useful Life (RUL) Prediction: Analyze historical data using algorithms to predict an asset’s remaining lifespan. For instance, a power company built an aging model for generator stator windings using five years of operational data and environmental factors, accurately predicting an 18-month lifespan. This allowed for timely spare part procurement and downtime scheduling, avoiding unplanned outages while maximizing the windings’ utility.

3. Precision Spare Part Management: Avoiding “Improper Parts Usage” That Accelerates Aging

Poor-quality spare parts, incorrect specifications, and improper storage can act as “hidden killers” of asset aging. Extending asset lifespan requires strengthening spare part management to build a solid “protective wall.”

Spare Part Classification and Inventory Optimization: Categorize spare parts into A, B, and C classes based on “value-importance.” For example, Class A parts (e.g., generator rotors) should maintain minimum safety stock with emergency supply agreements; Class B parts (e.g., motor bearings) should be stocked based on “consumption rate + lead time”; Class C parts (e.g., screws) can be purchased on demand. A chemical company reduced spare part inventory costs by 35% and shortened critical part delivery times from seven days to two days through classification management.

Spare Part Quality Traceability: Establish a full lifecycle traceability system by verifying supplier qualifications (e.g., ISO 9001 certification) during procurement, recording batch numbers upon storage, and allocating parts to specific equipment during issuance. For instance, a water pump failure caused by non-original sealing gaskets led to frequent motor overloads, shortening its lifespan by 40%. Strict quality control can prevent such issues.

4. Full Lifecycle Data Tracking: Continuously Optimizing Management Strategies

Asset management is an ongoing process from procurement to disposal. Only by recording data throughout the lifecycle and analyzing issues can the root causes of aging be identified, ensuring long-term stability in extending asset lifespan.

Digital Asset Ledger: Create an “electronic profile card” for each asset, recording procurement dates, maintenance logs, failure causes, and repair costs. For example, an office building’s elevator ledger revealed that 60% of failures were door mechanism issues occurring mostly during the rainy season. Adding waterproof covers reduced failures by 75%, extending the elevator’s lifespan by three years.

Data Review and Optimization: Conduct quarterly reviews of asset data to analyze reasons for accelerated aging (e.g., delayed maintenance, improper use, or spare part issues). A manufacturing company discovered that equipment used during the second shift aged 20% faster due to operators skipping preheating procedures. After enhancing training, the difference narrowed to less than 5%.

II. Professional Tools: How SAMEX EAM Makes Extending Asset Lifespan More Efficient

In practice, many companies face “execution challenges”: manual plans are prone to omissions, sensor data is disconnected from work orders, and scattered ledgers hinder analysis. SAMEX EAM (Enterprise Asset Management System) integrates these strategies into a unified platform, turning “theory” into “practice.”

The dynamic maintenance planning feature in SAMEX EAM can automatically generate work orders based on asset parameters and push them to responsible personnel 30 days in advance. It also links SOPs and spare part inventory, reducing maintenance work order omission rates from 15% to 0% for a steel company, extending equipment lifespan by 25%. For predictive maintenance, it seamlessly integrates IoT data to generate “health reports” and automatically alerts and analyzes fault points. A petrochemical company using this reduced unplanned downtime by 40% and extended the lifespan of core equipment by 1.8 years.

The spare part management module supports ABC classification, intelligent restocking, and RFID traceability. When maintenance personnel issue parts, the system automatically verifies if the “part matches the equipment.” A university laboratory in Hong Kong reduced spare part mismatches to 0% and equipment failures by 60% after implementation.

Additionally, SAMEX EAM’s asset ledger records the full lifecycle of data, generating “failure rate trend charts” and “maintenance cost tables” to help companies identify aging root causes. An automotive factory discovered that equipment aged quickly due to insufficient trial runs after maintenance. Adjusting the process reduced aging speed by 30%. SAMEX EAM is not just a “tool” but a “collaborative partner” in extending asset lifespan.

III. Extending Asset Lifespan: Creating Multiple Values for Enterprises

When strategies for extending asset lifespan are implemented, companies gain more than just prolonged asset usage—they achieve comprehensive value enhancement.

1. Significantly Reducing Operational Costs

Extending asset lifespan reduces replacement frequency. For example, an electric motor originally replaced every five years can now last seven years, saving 100,000-200,000 yuan per unit in procurement costs. Maintenance costs also decrease. Data from one company shows that extending asset lifespan reduced annual repair costs by 28% and spare part inventory capital by 40%, directly converting savings into profits.

2. Enhancing Production and Service Stability

Asset aging is a primary cause of downtime. Extending asset lifespan significantly reduces unplanned downtime. A steel mill reduced annual downtime from 120 hours to 40 hours, increasing production capacity by 15%, while order fulfillment rates rose from 85% to 98%. Similarly, extending the lifespan of MRI equipment in hospitals prevents delays in appointment scheduling, greatly improving customer experience.

3. Strengthening Compliance and Risk Management

Industries such as chemical and medical have strict compliance requirements for assets. The standardized maintenance and data traceability systems established during lifespan extension ensure regulatory compliance (e.g., GMP standards), avoiding fines. A power company identified transformer aging risks through predictive maintenance, addressing them in time to prevent grid accidents, thereby reducing safety losses and brand impacts.

4. Supporting Strategic Decision-Making

The asset data accumulated during lifespan extension (e.g., maintenance costs, failure rates, remaining lifespan) helps companies devise rational replacement plans. For example, one batch of eight-year-old equipment with maintenance costs exceeding new equipment depreciation was replaced promptly, while another batch of five-year-old equipment was optimized for maintenance and extended by three years, avoiding premature replacement. Data-driven decisions lead to more efficient asset allocation.

Extending asset lifespan is not a single technical action but a systematic project encompassing strategies, technologies, and tools. For companies struggling with asset aging, adopting scientific methods and professional tools (such as SAMEX EAM) not only slows asset aging but also transforms assets into “cost-reduction engines,” securing a competitive edge in the market.