With the rapid development of technology, the integration of Enterprise Asset Management (EAM) and Predictive Maintenance (PdM) has become a core trend in modern equipment management. This integration not only helps enterprises reduce operational costs but also improves asset efficiency and extends equipment lifespan. This article will explore the background, technical foundations, implementation methods, and future development directions of the integration of Predictive Maintenance and EAM, helping enterprises understand how to leverage this technology to enhance competitiveness.

I. The Background and Importance of Predictive Maintenance and EAM

1.1 Why Integration Is an Inevitable Trend

In the 1950s, vibration analysis technology was first used in the aviation and military sectors to monitor equipment conditions, laying the foundation for the development of Predictive Maintenance. With advancements in computer and sensor technologies, Predictive Maintenance gradually began to be applied in industrial fields such as manufacturing and energy in the 1970s.

As equipment management becomes increasingly complex, traditional planned maintenance alone can no longer meet the growing demands of modern enterprises. By the 21st century, the emergence of technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data has further propelled the concept and application of Predictive Maintenance, making it a crucial part of intelligent asset management.

The integration of Predictive Maintenance and EAM has become an inevitable trend because it enables enterprises to achieve superior management results on multiple levels. By predicting faults in advance and taking preventive measures, enterprises can reduce emergency repairs and downtime, avoiding production losses caused by equipment failures and effectively lowering costs. Furthermore, data-driven decision-making can optimize maintenance processes and enhance resource utilization, allowing enterprises to allocate manpower, materials, and financial resources more efficiently to maximize the value of each resource.

Continuous monitoring of equipment health helps enterprises extend equipment lifespan. Through precise fault prediction and maintenance planning, equipment operating efficiency can be maintained at optimal levels, thereby maximizing asset return on investment. These advantages make the integration of Predictive Maintenance and EAM a necessary choice for modern equipment management and a crucial strategic direction for enterprises to enhance competitiveness.

II. Core Concepts and Technical Foundations of Predictive Maintenance

2.1 Definition of Predictive Maintenance

The concept of Predictive Maintenance (PdM) can be traced back to the 1950s. At that time, with the advancement of industrial technology, people began to explore how to use equipment operation data to predict faults and conduct maintenance in advance, reducing downtime and maintenance costs.

2.2 Key Technologies

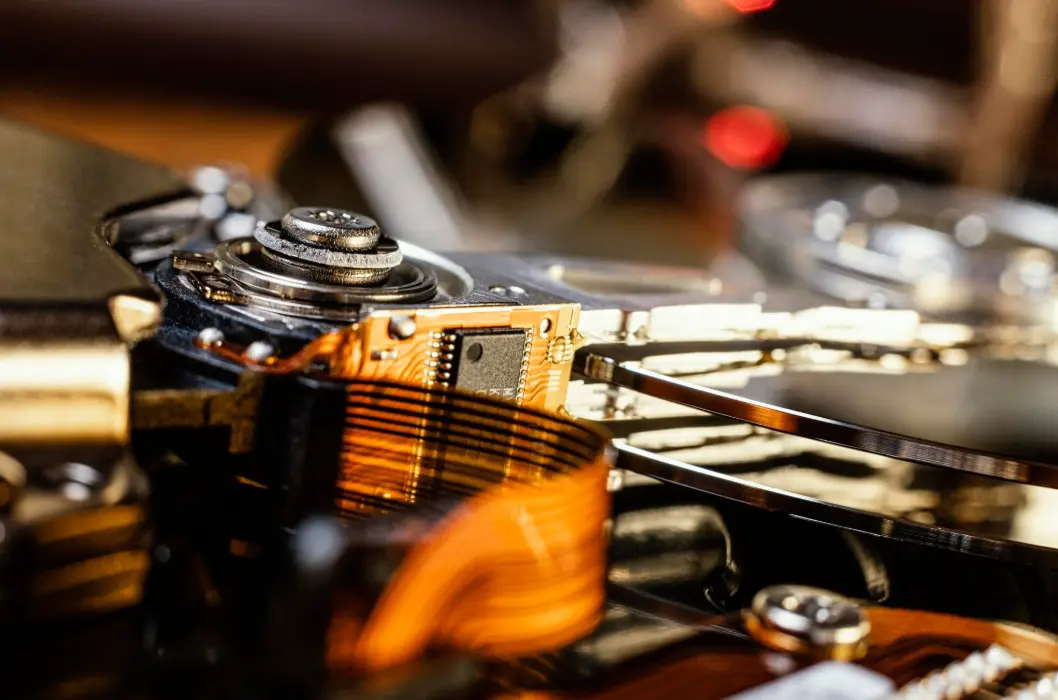

The implementation of Predictive Maintenance relies on the synergy of several advanced technologies, among which IoT plays an indispensable role. By deploying various sensors, IoT can continuously collect equipment operation data, enabling real-time monitoring of equipment conditions and providing a foundation for fault prediction.

Artificial Intelligence (AI) processes these data, using powerful algorithms to analyze equipment operation patterns, identify potential fault signs, and generate maintenance recommendations. Machine Learning (ML) further enhances prediction accuracy by analyzing vast amounts of historical data and operational records, continuously optimizing prediction models to allow systems to more precisely identify potential faults.

Sensor technology, as the core of data collection, captures key indicators such as temperature, vibration, and pressure, helping to detect subtle changes in equipment and ensuring the foundational data for Predictive Maintenance is comprehensive and reliable. The integration of these technologies enables Predictive Maintenance to break through the limitations of traditional maintenance methods and provide enterprises with more intelligent solutions.

2.3 Comparison with Traditional Maintenance Methods

Compared to traditional planned maintenance and reactive maintenance, Predictive Maintenance demonstrates significant advantages. Traditional planned maintenance is typically conducted based on fixed schedules, making it inflexible in responding to changes in equipment conditions, which often leads to over-maintenance or under-maintenance. Reactive maintenance, on the other hand, takes action only after faults occur, often resulting in production interruptions and high repair costs.

Predictive Maintenance, based on the actual operating conditions of equipment, uses precise fault predictions to help enterprises take action before faults occur, avoiding downtime and losses. This data-driven maintenance approach is not only more efficient, maximizing resource utilization, but also more economical, reducing unnecessary maintenance and extra expenses.

Moreover, Predictive Maintenance is more reliable. By predicting fault risks in advance, enterprises can effectively minimize downtime and ensure the stability of production processes. These features make Predictive Maintenance an ideal choice for modern equipment management, providing critical technical support for enterprises in highly competitive markets.

III. Functions and Value of EAM

3.1 The Role of EAM

As a comprehensive asset management tool, EAM systems help enterprises achieve digital transformation and improve the efficiency and accuracy of asset management. By centrally managing all equipment information, EAM systems enable visualized asset management, allowing enterprises to clearly understand the status and usage of each asset, thereby facilitating the formulation of corresponding management strategies.

In terms of maintenance, EAM systems, based on the actual operating conditions of equipment, assist managers in formulating reasonable maintenance plans, reducing downtime caused by equipment failures and ensuring the stability of production processes. EAM systems also optimize resource allocation, efficiently distributing manpower, materials, and financial resources to enhance overall operational efficiency, thereby lowering costs and increasing resource utilization.

3.2 How EAM Supports Predictive Maintenance

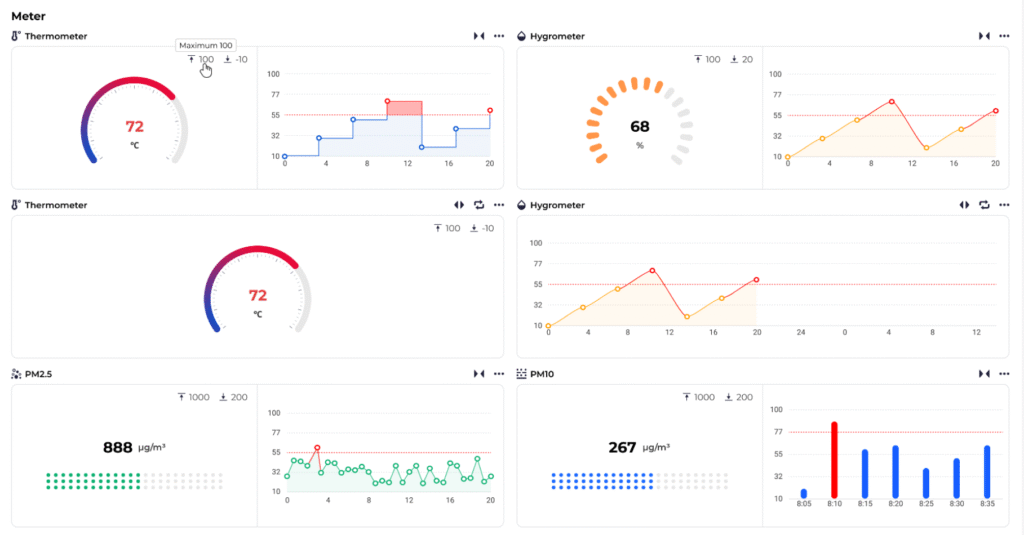

The combination of EAM systems and Predictive Maintenance technologies provides enterprises with more intelligent maintenance solutions. EAM systems can collect and store equipment operation data and integrate these data into visualized reports, helping managers comprehensively understand equipment operating conditions.

Based on Predictive Maintenance analysis results, EAM systems can automatically trigger maintenance tasks, achieving automation in maintenance processes and reducing the need for manual intervention. Through in-depth data analysis, EAM systems offer decision support to managers, helping them formulate more precise maintenance strategies and improving the efficiency and effectiveness of maintenance work. This seamless integration of technologies enables enterprises to better address equipment management challenges.

IV. Implementation Methods for the Integration of Predictive Maintenance and EAM

4.1 Technology Deployment

The deployment of Predictive Maintenance technologies is a key step in achieving integration, with IoT sensors and AI technologies playing vital roles. Enterprises need to install appropriate IoT sensors, such as temperature sensors and vibration sensors, based on equipment characteristics and operational requirements to capture subtle changes during equipment operation, ensuring comprehensive and accurate monitoring.

4.2 Data Integration

Data integration is the foundation of the entire process. The data collected by these sensors are centrally imported into the EAM system for storage and management, providing reliable data support for subsequent analysis and helping enterprises establish complete equipment operation records. AI algorithms can identify abnormal patterns in equipment operation, predict potential faults in advance, and generate specific maintenance recommendations, enabling enterprises to take effective measures before faults occur, thereby reducing repair costs and downtime.

4.3 Process Optimization

After completing the above two steps, process optimization becomes the final step in integration. Enterprises can set up dedicated Predictive Maintenance workflows within the EAM system to make maintenance work more efficient and automated. For example, when AI algorithms detect fault signs, the system can automatically send fault warning notifications to relevant managers, ensuring issues are addressed promptly.

The EAM system can also automatically generate maintenance work orders and schedule maintenance tasks based on Predictive Maintenance results. Additionally, the system can dynamically adjust maintenance plans based on real-time equipment conditions, ensuring the flexibility and specificity of maintenance work. This process optimization not only improves the efficiency of maintenance work but also maximizes equipment uptime and lifespan, creating greater value for enterprises.

V. Specific Solutions and Future Development Trends

5.1 Challenges of Integration

Despite the enormous potential of integrating Predictive Maintenance and EAM systems, enterprises still face several challenges during implementation. The cost of technology is one of the most significant obstacles. Deploying IoT sensors and applying AI technologies require substantial financial support, which may affect the normal operation of other business areas for enterprises with limited budgets.

Data security issues are also critical. The large amount of data generated during equipment operation may be vulnerable to cyberattacks during storage and transmission, leading to the leakage or damage of sensitive information and threatening the operational stability of enterprises.

Moreover, the successful application of technology depends on employee skill levels. Many enterprises’ technical teams may lack the expertise required to operate EAM systems and Predictive Maintenance technologies, which diminishes the effectiveness of technology implementation. These challenges are not insurmountable but do pose significant barriers to the advancement of integration.

5.2 Solutions

To effectively address challenges such as technology costs, data security, and skill shortages, selecting a robust and flexible EAM system is crucial. Solutions like SAMEX EAM have already prepared for the integration of IoT sensors and AI technologies, allowing enterprises to leverage its powerful technical support without additional investment in secondary development.

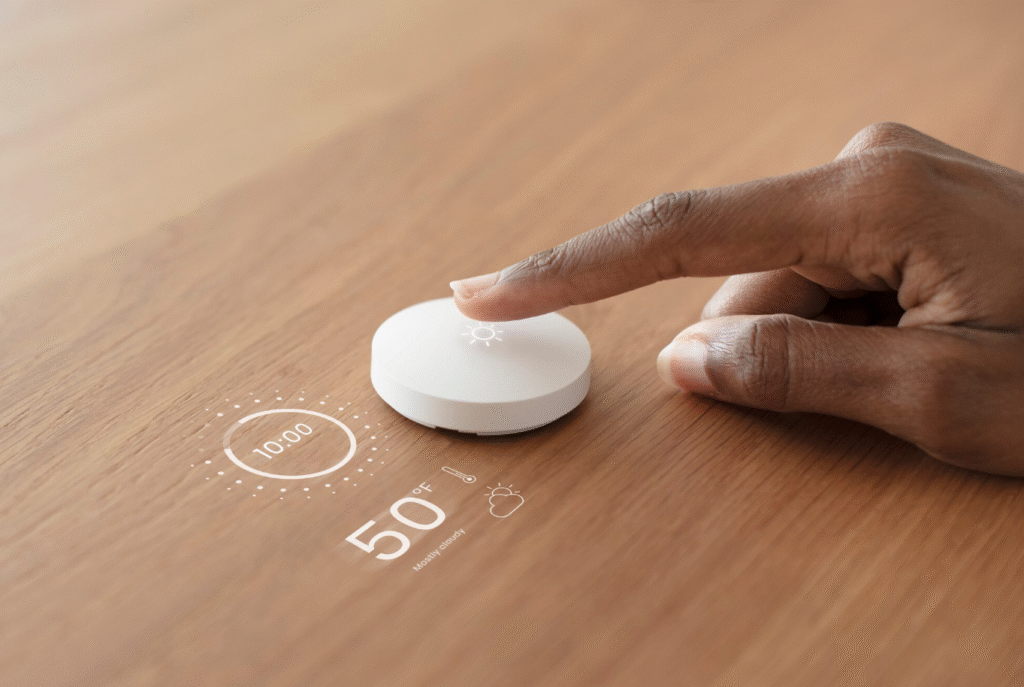

SAMEX EAM offers both cloud deployment and on-premise deployment options, enabling enterprises to choose the most suitable method based on their needs while maximizing data privacy and security. Moreover, its visualized process editor completely eliminates technical barriers, allowing enterprises to easily design customized features that fit their business needs without any programming knowledge.

More importantly, SAMEX has a professional development team capable of tailoring personalized solutions based on customer-specific requirements, ensuring the maximum effectiveness of technology applications. Such systems not only help enterprises overcome challenges but also provide a reliable foundation for the intelligent upgrade of asset management, enabling enterprises to progress steadily in digital transformation.

For enterprises seeking a more lightweight solution focused on inspection and patrol tasks, 313FM is an excellent alternative. Compared to EAM systems, 313FM specializes in streamlining inspection processes while supporting IoT sensor integration for real-time monitoring. Its simplicity and targeted functionality make it an ideal choice for businesses prioritizing operational efficiency without the complexity of full-scale asset management systems.

5.3 Future Trends

Looking ahead, as technology continues to evolve, the integration of Predictive Maintenance and EAM will move toward comprehensive intelligence. McKinsey’s report, “Unlocking the Potential of the Internet of Things“, suggests that Predictive Maintenance supported by IoT and AI technologies can reduce average equipment maintenance costs by 30% and decrease failure rates by 70%. The application of 5G networks and edge computing will further enhance data transmission speed and analytical capabilities, enabling enterprises to achieve more immediate and precise equipment condition monitoring and response.

Deloitte’s report, “Predictive Maintenance and the Smart Factory“, points out that future EAM systems will be capable of autonomously executing maintenance tasks and achieving higher levels of automation in fault prediction and resource allocation, significantly reducing the need for manual intervention. Combining EAM systems with Predictive Maintenance can help enterprises achieve up to a 25% improvement in asset operational efficiency.

As IoT technology matures and intelligence deepens, enterprises will be able to better optimize asset management during digital transformation, thereby improving operational efficiency and market competitiveness. The integration of Predictive Maintenance and EAM is not just a technological advancement but also a cornerstone of smart factory construction, creating unprecedented value space for enterprises.