Across the industrial production chain, production equipment is the core engine, and routine equipment maintenance is the “stethoscope” and “shield” that keeps this engine running steadily. Whether it’s a machine tool in a machining workshop, a reactor in a chemical plant, or an AGV robot in logistics warehousing, only standardized routine equipment maintenance can keep equipment in optimal condition at all times. This preventive, periodic verification directly impacts an enterprise’s safety baseline, production efficiency, and operating outcomes, making it a vital foundation for steady development. So, what key missions does daily inspection of production equipment actually carry?

1.Fortify the Safety Line: Routine Equipment Maintenance Eliminates Accident Hazards

Through meticulous checks of critical components, routine equipment maintenance clears these “hidden bombs” in advance. In the chemical industry, staff use routine equipment maintenance to focus on the sensitivity

Through meticulous checks of critical components, routine equipment maintenance clears these “hidden bombs” in advance. In the chemical industry, staff use routine equipment maintenance to focus on the sensitivity of reactor pressure valves and temperature sensor readings to avoid dangers caused by overpressure leaks; in machining workshops, inspectors check the firmness of machine guards and the effectiveness of emergency stop buttons to prevent entanglement injuries during operation.

For any safety hazards discovered during inspections, a rapid response mechanism should be established to close the loop in the shortest possible time, fully meeting industry safety and compliance requirements.

2.Ensure Continuous Production: Routine Equipment Maintenance Reduces Downtime Losses

Unplanned downtime is manufacturing’s “cost black hole.” As ABB’s press release “Industrial downtime costs up to $500,000 per hour and can happen every week” makes clear, hourly losses can reach as high as $500,000, with many companies falling in the $10,000–$500,000 per hour range. These losses are far from isolated cases: a sudden production line stoppage can trigger a chain reaction of delayed orders, raw material waste, and idle labor—consequences that far exceed expectations.

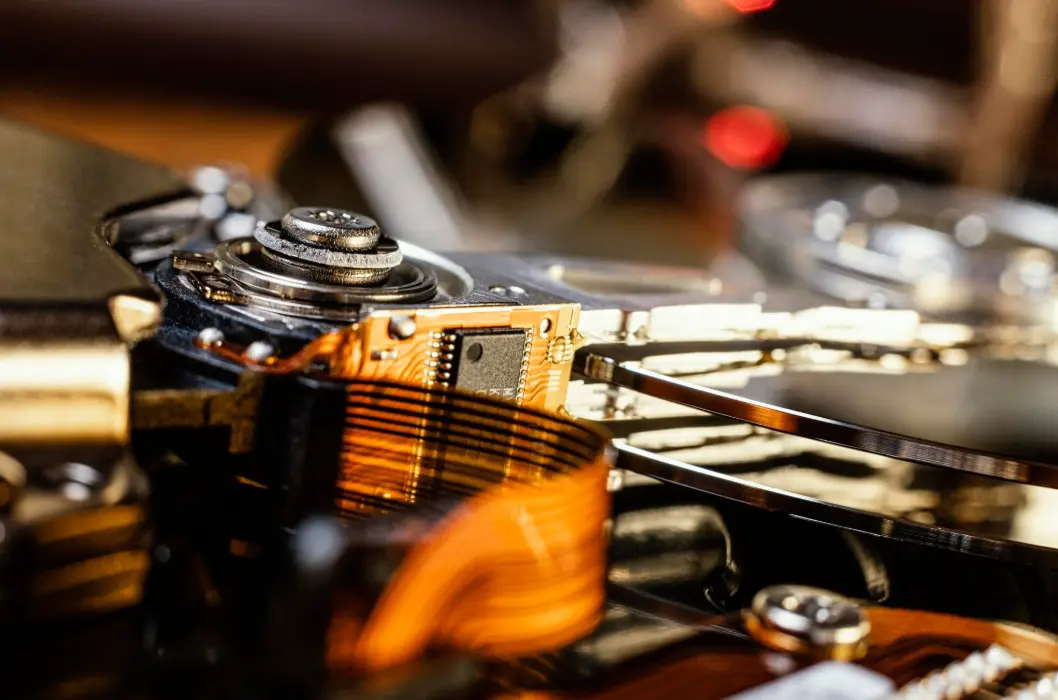

One of the core values of routine equipment maintenance is capturing “early fault signals,” resolving minor issues at the nascent stage to prevent them from escalating into major failures that cause downtime. In automotive assembly lines, the lubrication of robotic joints and the operating noise of servo motors are key focuses of routine equipment maintenance; timely lubrication or bearing replacement can effectively prevent a full line shutdown. In logistics and warehousing, inspectors use routine equipment maintenance to track AGV robots’ battery endurance and navigation sensor accuracy, preventing sudden crashes during operation.

Companies can preset inspection cycles by equipment type, define clear tasks, and record operating data; by analyzing trends, they can forecast potential downtime risks and shift from reactive repairs to proactive prevention.

3.Extend Equipment Lifespan: Routine Equipment Maintenance Lowers Asset Costs

Production equipment is an expensive fixed asset—investment in a single production line often reaches millions or tens of millions in local currency. Its service life directly affects ROI. Through refined care and maintenance, routine equipment maintenance effectively slows wear, delays aging, and prevents shortened lifespans caused by long-term “running while sick.”

For heavy machinery engines, inspectors focus on oil levels and filter cleanliness during routine equipment maintenance; simple actions like regular oil changes can extend engine life by more than 30%. In printing, timely cleaning and calibration of rollers during routine equipment maintenance avoids ink build-up and abrasion, significantly reducing the high cost of roller replacement.

Enterprises should fully document every inspection, service, and repair to form a dedicated “health record,” helping managers understand wear patterns, optimize maintenance plans, and maximize asset utilization.

4.Stabilize Product Quality: Routine Equipment Maintenance Mitigates Quality Risks

Equipment precision directly determines product quality. If parameters drift or parts wear, products can easily suffer dimensional deviations or performance failures, leading to complaints, returns, and reputational damage. Routine equipment maintenance provides robust quality assurance through regular calibration and stable operation. In electronics, the nozzle precision and placement pressure of SMT machines are core items in routine equipment maintenance—accurate checks effectively prevent misaligned components or cold solder joints. In food processing, routine equipment maintenance verifies the temperature uniformity of sterilizers to ensure compliance with food safety standards and prevent bacterial exceedances.

Enterprises can preset standard ranges for critical equipment parameters; inspection data should be compared in real time, with immediate alarms when thresholds are exceeded. This proactive measure ensures equipment always operates within qualified ranges and product quality remains consistent throughout the production process.

5.Control Maintenance Costs: Routine Equipment Maintenance Prevents Cost Surges

Repair costs for equipment failures grow “exponentially.” Minor issues found early—like replacing a seal or tightening bolts—may cost just a few dollars and an hour of work. If delayed into major failures—such as spindle fractures or motor burnouts—repair costs can skyrocket into the thousands, with downtime stretching to days. The key role of routine equipment maintenance is identifying these “minor ailments” in time to prevent them from turning into “major illnesses.”

For a commonly used factory water pump, detecting slight leakage during inspection (often due to aged seals) might be fixed for the equivalent of a small sum; ignoring inspections can lead to casing corrosion and motor water ingress, ultimately causing repairs exceeding thousands and two days of downtime. By analyzing inspection data, enterprises can quantify failure costs, clearly showing the difference between “preventive maintenance” and “breakdown repair” to optimize budget allocation. Data indicates that standardized routine equipment maintenance can reduce total repair costs by 20%–30%.

6.Meet Compliance Requirements: Routine Equipment Maintenance Supports Audits and Acceptance

Industries such as chemicals, pharmaceuticals, energy, and food have explicit regulatory requirements for production equipment. Companies must regularly provide inspection and maintenance records as core evidence for compliance audits; failure to implement routine equipment maintenance may result in fines or enforced shutdowns.

In pharmaceutical GMP certification, periodic inspection and calibration records for production equipment are mandatory; in the energy sector, daily inspection records for special equipment such as boilers and cranes are critical references for statutory testing.

Enterprises should establish standardized routine equipment maintenance reporting systems covering inspection times, personnel, issues, and resolutions, ensuring complete and traceable records that can be retrieved directly during audits—preventing omissions or tampering in manual logs and helping companies navigate regulatory checks with ease.

In conclusion, routine equipment maintenance is anything but a formalistic process—it’s a critical lever for achieving “zero safety incidents, zero production interruptions, zero quality defects, and optimal costs.” Covering the entire equipment management cycle, it plays a vital role in identifying safety hazards, extending equipment life, stabilizing product quality and controlling maintenance expenses.

Today, equipment management systems like SAMEX EAM are gaining widespread adoption. With “full life-cycle equipment management” as their core logic, they turn inspection data into actionable management insights, shifting equipment governance from “passive response” to “proactive control.” Combining standardized routine equipment maintenance with professional management systems provides solid support for an enterprise’s long-term, stable development.