I. The “Century Challenge” of Traditional Building Asset Management

In large commercial complexes, office buildings, hospitals, industrial parks, and airports, the management of fixed assets and key equipment in traditional buildings has always been a headache. Unlike the efficiency and precision offered by Smart Building solutions, traditional methods heavily rely on manual ledger entries and periodic inventory checks. Equipment failures, low operational efficiency, and severe asset loss are the main challenges faced by managers, highlighting the urgent need for transitioning to Smart Building technologies.

- Low inventory efficiency: A comprehensive asset inventory often takes days or even weeks, requires work stoppages and significant manpower input, and still frequently results in errors.

- Inaccurate location information:”The item is clearly somewhere in this building, but we just can’t find it!” — Expensive mobile devices, specialized tools, and spare parts often become “useless” due to the inability to locate them quickly.

- Lack of lifecycle management:When was the equipment purchased? When does it need maintenance? When should it be decommissioned? The absence of dynamic data records leads to insufficient preventive maintenance, resulting in either “over-maintenance” or “under-maintenance,” increasing the risk of unexpected equipment downtime.

- Severe asset loss:Due to the lack of effective monitoring methods, the theft, loss, or unauthorized movement of assets (especially high-value assets) is difficult to trace and prevent.

These issues not only increase operating costs but also bring safety risks. At the same time, patrol and inspection work often relies on manual records, with scattered data that is difficult to trace, leading to problems that cannot be precisely located and even missing the best maintenance timing.

As building scales expand and equipment types diversify, traditional management methods are proving inadequate. Managers must address challenges such as equipment lifecycle management, real-time data collection and analysis, and cross-department collaboration, but lack effective tools to achieve these goals. How to improve equipment maintenance efficiency, ensure asset safety, and reduce operating costs has become a pressing issue for every building manager. Faced with these pain points, the construction of a smart building asset management system has become an inevitable trend.

II. IoT Technology: The “Nerve Endings” Giving Life to Smart Buildings

The construction of smart buildings is not only an inevitable result of technological development but also the core means of solving building management pain points. With the acceleration of urbanization, building scales and complexity continue to increase, and traditional manual management methods can no longer meet the needs of modern buildings. Smart buildings use digital methods to deeply integrate and optimize building assets, equipment, and operational processes, enabling assets to be visible, controllable, and predictable.

The core of smart buildings lies in “data-driven” management. By collecting and analyzing building operational data in real time, managers can accurately understand equipment status, optimize resource allocation, and respond promptly to emergencies. Especially in high-density urban environments, smart buildings can effectively address issues such as limited space and scarce resources, providing more efficient and safer solutions for building operations. Furthermore, smart buildings promote sustainable development by monitoring and optimizing energy consumption to achieve green energy-saving goals and reduce carbon emissions. These are advantages that traditional buildings cannot achieve.

III. Three Steps to Build a Smart Building IoT Asset Management System

Step 1: Asset Digitization — Define “Identity”

Attach or install appropriate IoT smart tags (such as RFID or UWB tags) to each asset that needs management, and input detailed information (name, model, purchase date, supplier, warranty period, etc.) into the asset management platform to establish a one-to-one digital identity. This is the foundation for all smart operations.

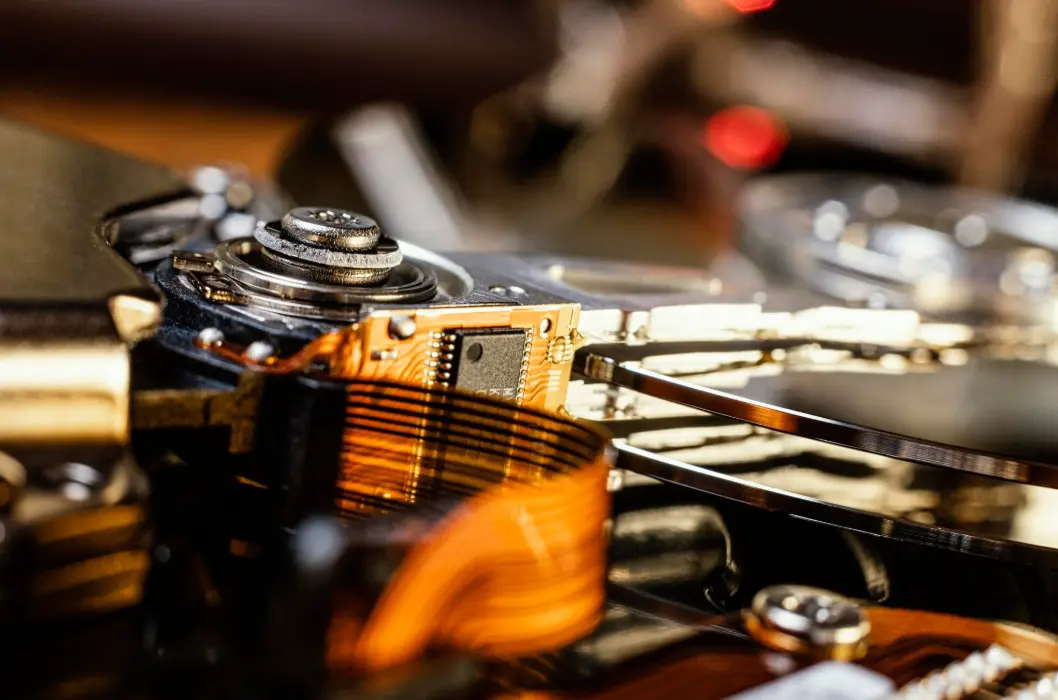

- IoT sensors are the basic components of smart buildings, used to collect equipment operation data such as temperature, humidity, vibration, and energy consumption. Sensors are installed on equipment and transmit data to the central system via wireless networks, allowing managers to monitor equipment status in real time and detect potential faults in advance.

- RFID (Radio Frequency Identification) tags can be used for asset identification and location tracking. Each building asset can be bound to an RFID tag, enabling quick identification of asset location and status through readers, avoiding asset loss or misplacement, and improving inspection efficiency.

- Bluetooth and NFC technologies have advantages in short-range data transmission. For example, inspection personnel can scan NFC tags using mobile phones or handheld devices to quickly obtain equipment information and record inspection results. Bluetooth technology is suitable for automatic connection and data synchronization between devices, further improving operational efficiency.

Step 2: Infrastructure Deployment — Build the “Network”

Based on the building’s physical environment and asset management precision requirements, scientifically deploy readers, positioning base stations, IoT gateways, and other infrastructure to ensure seamless network coverage in the required areas, capable of capturing all data emitted by asset tags without blind spots.

IoT device-collected data is aggregated to the cloud platform. Through big data analysis and artificial intelligence technology, managers can generate equipment health reports, predict faults, and optimize maintenance plans. This data-driven approach not only improves management efficiency but also enables predictive and precise equipment maintenance.

Step 3: Platform Construction and Integration — Build the “Brain”

Smart buildings are not just about controlling lights and air conditioning; they involve deep digitalization of core assets and operational processes. Through IoT technology, we transform cold assets and tedious inspections into visible, controllable, and predictable processes, helping managers reduce costs, ensure safety, and ultimately achieve true “smartification” of buildings.

To build a truly smart building, the platform should have the following core functionalities:

Real-time monitoring and data collection:

Using IoT sensors, RFID tags, Bluetooth, and NFC technologies, collect operational data from all building equipment in real time, including temperature, humidity, energy consumption, vibration, and pressure. Achieve real-time monitoring of equipment status to ensure data accuracy and timeliness. This helps quickly identify faults, reduce equipment downtime, and ensure stable building operations.

Data analysis and fault prediction:

The platform should have robust data analysis capabilities. By analyzing collected operational data, it can generate equipment health reports, operational trend analyses, and fault prediction models. Using artificial intelligence and machine learning algorithms, it can predict equipment faults and optimize maintenance plans, reducing sudden downtime incidents and maintenance costs.

Asset lifecycle management:

The platform should cover the entire lifecycle of assets, including asset registration, procurement, installation, usage, maintenance, upgrades, and decommissioning. This ensures comprehensive asset dynamics, reduces asset loss and duplicate purchases, and improves management efficiency.

Smart patrol and inspection:

The platform should support intelligent management of inspection tasks, including task assignment, real-time recording, data uploading, and report generation. Combining NFC tags and mobile applications, inspection personnel can scan tags to quickly record equipment status and upload data to the cloud system, improving inspection efficiency, reducing manual recording errors, and ensuring data traceability.

Scalability and customization:

To meet the needs of different building types and adapt to future technological developments, the platform should have high scalability, allowing functional expansion based on building scale and requirements while supporting customized services.

Through these core functionalities, a smart building management platform can achieve comprehensive digital management of building assets and operational processes, helping managers reduce costs, ensure safety, improve operational efficiency, and ultimately achieve true smartification of buildings.

IV. Process Reshaping and Implementation — Activate “Value”

The intelligentization of asset management systems is not simply a technological upgrade but a profound transformation of management philosophy. It serves as a solid foundation for constructing smart buildings, making previously “silent” assets become “transparent,” “controllable,” and “intelligent.”

SAMEX EAM (Enterprise Asset Management System) digitizes the full lifecycle management of building assets, providing one-stop services from asset registration and maintenance planning to fault handling. Combined with IoT sensors and RFID technology, SAMEX EAM can monitor equipment status in real time, generate data reports, and optimize maintenance plans, offering efficient and precise management tools for building managers.

313FM Cloud Inspection Solution digitizes inspection tasks through mobile applications and cloud platforms. Inspection personnel can scan NFC tags to quickly record equipment information, upload it to the cloud system, and automatically generate inspection reports. Combined with IoT technology, the 313FM solution also supports equipment fault warnings and maintenance plan optimization, significantly improving inspection efficiency and data traceability.

Through these solutions, the smart building asset management system not only addresses traditional management pain points but also helps building managers achieve true digital transformation, moving towards a more efficient, safer, and sustainable future.