Hong Kong, as one of the cities with the highest population density globally, relies heavily on efficient management and maintenance of industrial and commercial facilities for their normal operations. In such a high-density environment, equipment maintenance not only affects production efficiency but also directly impacts public safety and the sustainable development of enterprises.

Therefore, constructing a comprehensive equipment maintenance management system is particularly important, especially with preventive safety features. This article will explore the core functions of equipment maintenance systems and analyze their necessity and application value in the context of Hong Kong’s unique environment.

I. Special Requirements for Equipment Maintenance in Hong Kong’s High-Density Environment

Whether it’s commercial facilities, public transportation systems, or high-rise buildings, the functionality of Hong Kong’s equipment maintenance systems must adapt to the complex needs of a high-density environment. The following analysis covers four aspects: space constraints, high usage rates, safety requirements, and environmental factors, which pose unique challenges to equipment maintenance in Hong Kong.

1. Maintenance Challenges Caused by Space Constraints

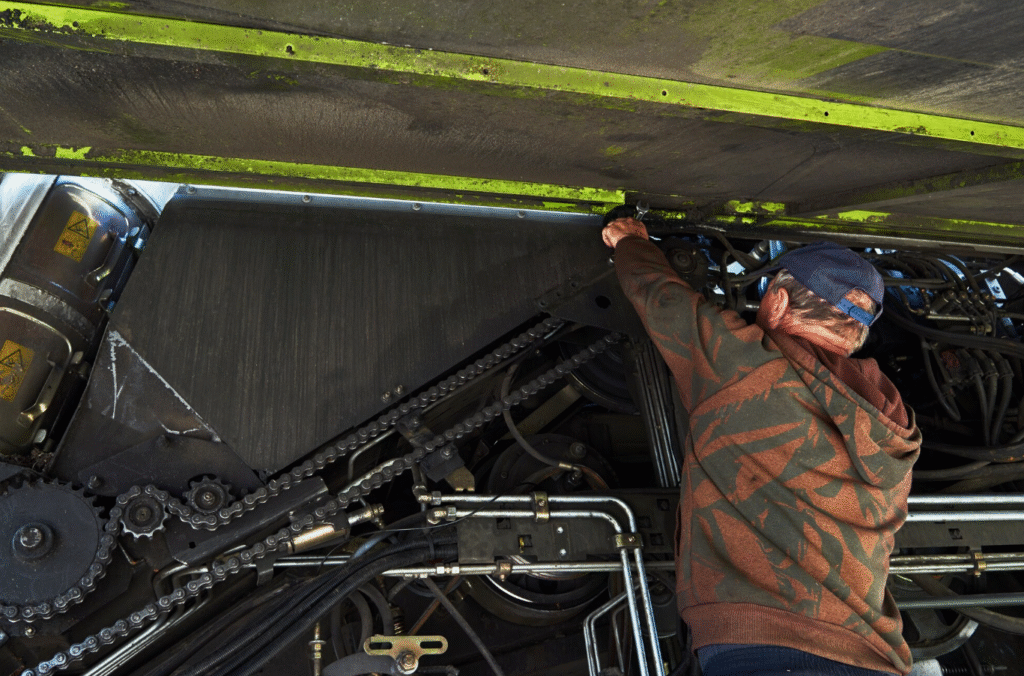

Hong Kong’s urban space is extremely limited, with buildings and facilities often developed vertically, resulting in a large number of high-rise buildings. In these structures, equipment such as elevators, air conditioning systems, and generators are often installed in basements, rooftops, or narrow machine rooms. This compact layout increases the complexity of maintenance work, as limited space can lead to poor heat dissipation, accelerating equipment aging and failures. Maintenance personnel may face operational restrictions in confined spaces, and the proximity of equipment may increase the risk of mutual interference and faults.

2. Increased Risk of Failure Due to High Usage Rates

Economic activities in Hong Kong are frequent, and the intensity of equipment use far exceeds that of other regions. Prolonged high-load operation significantly raises the probability of equipment failure. For example, elevators in high-rise buildings are indispensable for daily life. Due to high population density, each elevator operates far more frequently than in other areas, leading to increased wear and tear and failure rates.

Similarly, Hong Kong’s public transportation systems, such as the MTR and buses, carry millions of passengers daily, with vehicles and track equipment under constant high-load operation. Without regular maintenance, the safety and efficiency of these systems would be severely compromised.

3. Stricter Safety Requirements

A high-density environment means that equipment failures could directly affect the safety of a large number of people. Therefore, equipment maintenance systems must adhere to higher safety standards. In Hong Kong’s buildings, fire safety equipment such as sprinkler systems and smoke detectors are critical for ensuring public safety. If these devices fail, the consequences could be catastrophic. Thus, equipment maintenance systems must conduct regular inspections and testing of fire safety equipment to ensure they remain in optimal working condition.

4. Additional Challenges Posed by Environmental Factors

Hong Kong is located in a subtropical region with consistently high humidity, and coastal areas are often affected by salt spray. These environmental conditions can accelerate the corrosion and aging of equipment’s metal components. For example, port machinery operating in such environments requires more frequent maintenance.

Additionally, Hong Kong experiences annual typhoons during summer, with strong winds and heavy rain potentially causing direct damage to equipment. Equipment maintenance systems need to include emergency response features to inspect and reinforce critical equipment before extreme weather events occur.

II. Core Functions of Equipment Maintenance Systems

Equipment maintenance systems can be categorized into four types based on usage scenarios: preventive maintenance, predictive maintenance, reactive maintenance, and breakdown maintenance.

Preventive maintenance is a strategy based on time or usage cycles, involving regular inspections and maintenance to reduce the likelihood of equipment failures. For example, regularly replacing elevator brakes or cleaning air conditioner filters to extend the equipment’s lifespan.

Predictive maintenance, on the other hand, is a maintenance approach based on data analysis and equipment condition monitoring. By collecting operational data through sensors and applying algorithms, it predicts potential failures, enabling proactive measures to be taken. For instance, monitoring the vibration and temperature data of generators to forecast wear and tear on components.

Reactive maintenance addresses minor issues that arise during equipment operation, such as adjusting operational parameters or replacing worn-out components. This type of maintenance is typically supplementary to preventive and predictive maintenance.

Breakdown maintenance involves repairing equipment after a failure has occurred. This approach often results in prolonged downtime and impacts production efficiency. As a result, enterprises aim to minimize the need for breakdown maintenance by prioritizing preventive and predictive measures.

To meet the requirements of these maintenance strategies, a comprehensive equipment maintenance system must possess the following core functions:

1. Real-Time Monitoring and Alarm Function

Using sensors and IoT technology, equipment maintenance systems can monitor equipment operation in real-time. When anomalies such as excessive temperatures or abnormal vibrations are detected, the system immediately issues alerts and notifies relevant personnel.

2. Data Analysis and Prediction Function

The system collects operational data and performs analysis to predict potential failure risks. For example, utilizing machine learning algorithms to analyze historical data and predict wear and tear on components, enabling timely maintenance scheduling.

3. Maintenance Plan Management Function

Based on equipment usage cycles and operational status, the system automatically generates maintenance plans and reminds technicians to perform inspections and maintenance on schedule. This function reduces human error and improves maintenance efficiency.

4. Fault Recording and Analysis Function

The system records detailed information about equipment failures, including the time, cause, and repair process. This data helps optimize maintenance strategies and provides technicians with references to prevent similar failures in the future.

5. Spare Parts Management Function

The system manages spare parts inventory, predicts demand, and interfaces with suppliers to ensure timely delivery of spare parts, reducing repair wait times. For example, in manufacturing industries, the system can predict replacement times for specific components based on operational data.

6. Performance Monitoring Function

Equipment maintenance systems monitor operational efficiency and energy consumption data to help enterprises optimize equipment usage and reduce operating costs. For instance, monitoring the energy consumption of air conditioning systems to optimize cooling efficiency.

III. Equipment Maintenance for Safety and Efficiency in High-Density Hong Kong

In Hong Kong’s high-density environment, the preventive safety features of equipment maintenance systems are not only critical for improving equipment efficiency but also essential for ensuring public safety and sustainable enterprise development. Advanced solutions like SAMEX FM/EAM stand out by offering exceptional facility management and enterprise asset management capabilities, enabling enterprises to achieve full lifecycle management of their equipment.

From preventive maintenance to real-time data analysis, SAMEX FM/EAM provides comprehensive maintenance strategies, ensuring efficient and safe equipment operation while simplifying complex maintenance workflows. These features not only elevate the standards of equipment management but also create higher operational efficiency for Hong Kong’s industrial and commercial facilities. As technology continues to advance, intelligent systems like SAMEX FM/EAM will play an even greater role in the future, helping Hong Kong maintain its competitive edge globally while driving sustainable urban development.