SAMEX Asset Management for Processing Plant

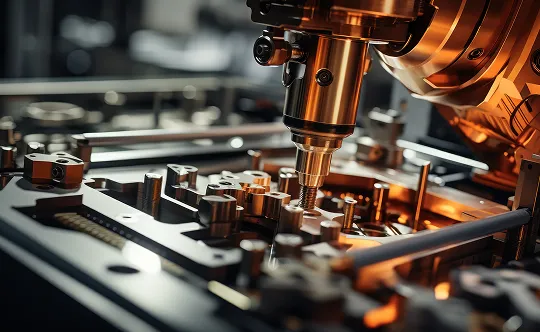

In any manufacturing industry, unexpected downtime of equipment on the production line can significantly impact the enterprise’s production plans, and in severe cases, can lead to the suspension of the entire production line. Effective asset and equipment management is not merely about maintaining the equipment itself; it is about providing an environmental safeguard for the enterprise’s production plans and product quality.

Management Dilemmas in the Manufacturing Industry

Virtually all manufacturing industries have the following requirements for production equipment: reducing equipment downtime to ensure production plans and product quality, enhancing maintenance efficiency, reducing maintenance costs, and eliminating hidden safety hazards. However, due to various reasons (such as the sheer number of assets and equipment, complex functions, varying requirements for weekly, monthly, and annual inspections, and the variability of professional maintenance personnel), most equipment maintenance departments still rely on traditional manual paper-based operations and lack standardized management. This ultimately results in excessive equipment downtime, low overall equipment efficiency, thereby affecting production schedules and product quality, and even more significantly, increasing production costs for enterprises.

The quantity of assets and equipment is immense

Complex Equipment Functionality

Inconsistent Maintenance Frequencies

High Turnover of Maintenance Personnel

SAMEX Asset and Equipment Service Management Philosophy

Why should processing plants choose SAMEX for asset management?

Currently, domestic enterprises face numerous issues in equipment management and maintenance. Some enterprises unilaterally pursue production output, either by delaying maintenance schedules, operating equipment beyond its capacity, or allowing equipment to run with faults. While some enterprises have established regular equipment maintenance and inspection systems, it is difficult to strictly enforce them when conflicts arise with profitability and production output. Some enterprises rush to meet deadlines, overworking their equipment, leading to frequent equipment failures and a declining effective operation rate. Others lack sufficient maintenance capabilities and management skills, making it difficult to address faults in imported equipment. Still, some enterprises blindly import foreign equipment, only to find that it cannot be put into production due to various reasons, ultimately becoming scrap metal. Such problems do exist in China, and some are quite severe. As the saying goes, “A workman must sharpen his tools if he wants to do his work well.” The management and maintenance of equipment are particularly important for the manufacturing industry.

By using SameX to manage your equipment assets, you can comprehensively enhance your equipment maintenance standards, improve efficiency, and thereby reduce unnecessary cost expenditures.

Significantly reduce equipment maintenance and repair costs

Significantly reduce the equipment failure rate, shorten the equipment repair cycle, and extend the equipment fault cycle

Significantly reduce inventory costs, eliminate obsolete spare parts, and improve enterprise inventory sharing and allocation capabilities.

Improve equipment reliability and reduce unexpected downtime losses

Enhance equipment performance and increase equipment output

Quickly establish equipment reliability models to reduce unexpected downtime

Basic Elements of a SAMEX Project Plan

Project objectives

Success indicator

Team collaboration

Budget

improve efficiency

Timetable and Scheduling

Communication plan

Project objectives

Success indicator

Team collaboration

Budget

improve efficiency

Timetable and Scheduling

Communication plan

Significantly reduce equipment maintenance and repair costs

- Improve employee safety, health and productivity;

- Improve efficiency and effectiveness;

- Enhance communication on equipment management methods;

- Enhance the consistency of equipment operation;

- Recognition from customers

Scientifically manage equipment assets

- Paperless management maximizes the avoidance of data loss;

- Convert manual experience into a systematic knowledge base;

- Plant Environment Patrol & Equipment Spot Check;

- Providing maintenance records helps to analyze the problem situation;

- Powerful Reporting Center.

Need Further Information ?